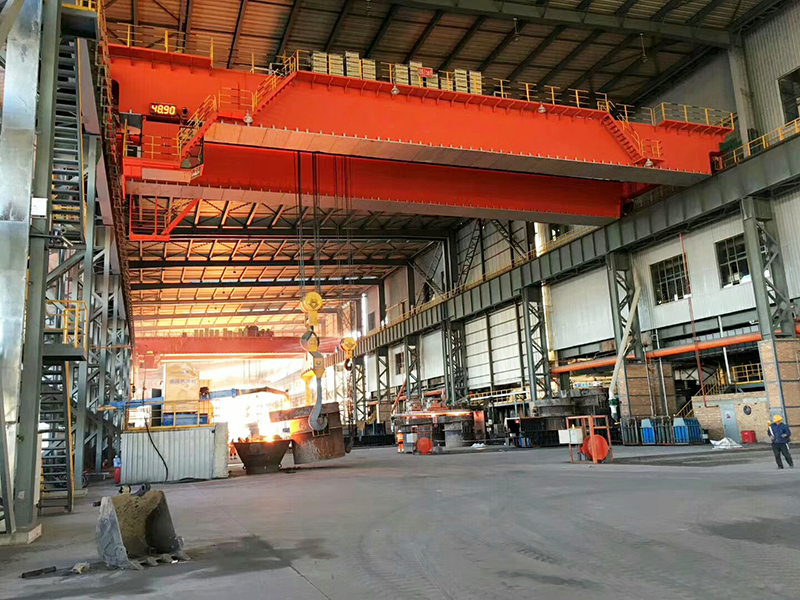

The steel industry is synonymous with heavy-duty operations, requiring robust equipment capable of handling extremely high loads. Among the critical machinery in steel mills, overhead cranes are indispensable. Specifically, a 100-ton overhead crane plays a pivotal role in handling heavy steel slabs, coils, ingots, and other substantial materials. A crucial factor that determines the performance, durability, and safety of these cranes lies in the materials used for the crane girders and hooks. Selecting the right materials requires careful consideration of mechanical properties, environmental conditions, fabrication processes, and long-term maintenance requirements.

1. Importance of Material Selection

The girders and hooks are the primary load-bearing components of a 100 ton overhead crane. The girders, typically in the form of main beams, support the trolley and hoist while spanning across the crane runway. The hooks connect the crane hoist to the load directly. Failures in these components can result in catastrophic accidents, production losses, and costly downtime. Therefore, the selection of suitable materials is crucial to:

-

Ensure the crane can safely handle 100 tons and dynamic loads during operation.

-

Provide resistance to fatigue due to repetitive loading.

-

Maintain structural integrity under high-temperature environments often present in steel mills.

-

Reduce maintenance costs and prolong service life.

2. Material Requirements for Crane Girders

The girders of a 100-ton overhead crane bear both the static load of the crane and the dynamic forces of moving heavy steel objects. The material used must exhibit high strength, toughness, and resistance to fatigue. Key requirements include:

-

High Yield and Tensile Strength: The material must withstand bending and shear stresses without permanent deformation. For a 100-ton crane, typical bending moments are substantial, and the material’s yield strength should be sufficient to prevent plastic deformation.

-

Good Toughness: Steel mills are high-impact environments. The girder overhead crane may experience sudden load shifts or accidental shocks. A tough material helps absorb energy without fracturing.

-

Weldability: Most crane girders are fabricated from welded steel plates and profiles. Materials must allow high-quality welding without cracking.

-

Fatigue Resistance: Continuous lifting and lowering create repeated stress cycles. The material should resist fatigue failure over prolonged operational periods.

-

Corrosion Resistance: Steel mills often have humid environments and exposure to chemical residues. Materials with moderate corrosion resistance reduce maintenance frequency.

Common Materials for Girders

-

High-Strength Structural Steel (Q345B / Q420B)

These steels are widely used for crane girders due to a combination of strength, toughness, and weldability. Typical mechanical properties:-

Yield Strength: 345–420 MPa

-

Tensile Strength: 470–550 MPa

-

Good ductility and impact resistance

-

Excellent weldability, allowing fabrication of large welded girders.

-

-

Steel Grades with Low Alloy Additions (e.g., 16Mn, Q460GJH)

Low alloy steels contain small amounts of manganese, nickel, and molybdenum to enhance toughness and fatigue resistance. For steel mills where the crane operates in higher temperatures or encounters higher fatigue loads, these steels are often preferred. -

Heat-Treated Steels

Some manufacturers opt for quenched and tempered steels to achieve higher strength while maintaining ductility. These are suitable when the steel mill crane girders face extreme loads or dynamic stress variations.

3. Material Selection for Crane Hooks

The hook is arguably the most critical component, as it directly supports the crane load. Material failure in the hook can lead to immediate hazards. Therefore, the material selection emphasizes toughness, hardness, fatigue resistance, and wear resistance.

-

High Strength: The hook must support the full rated load of 100 tons, plus a safety margin of 25–50%. This ensures it can handle accidental overloading or dynamic impacts.

-

Impact Toughness: Hooks often experience sudden loads and shocks during lifting. High toughness prevents brittle fracture.

-

Wear Resistance: Friction between the hook and slings, chains, or other lifting gear can cause wear over time. Hardened steel surfaces improve lifespan.

-

Fatigue Resistance: Repeated lifting operations create cyclic stresses. Material must resist fatigue cracking over thousands of cycles.

-

Weldability (Optional): Hooks are often cast or forged, but some may have welded components. Material should allow high-quality welding if required.

Common Materials for Hooks

-

Alloy Steel (40Cr, 45Cr, 35NiCrMo, 42CrMo)

-

High tensile strength (700–1100 MPa after quenching and tempering)

-

Excellent toughness and fatigue resistance

-

Suitable for forging, which enhances structural integrity and avoids internal defects.

-

-

Forged Carbon Steel Hooks (35SiMn, 40SiMn)

-

High wear and fatigue resistance

-

Good combination of strength and toughness

-

Often used in heavy-duty foundry cranes like 100-ton overhead cranes.

-

-

Heat-Treated Hooks

-

Hooks are usually quenched and tempered to achieve optimal hardness (typically 28–38 HRC) while maintaining toughness.

-

Surface induction hardening may be applied to improve wear resistance without compromising internal ductility.

-

4. Design Considerations Linked to Material Properties

Material selection must be integrated with the design of girders and hooks:

-

Girders: The cross-section (I-beam, box girder) and flange thickness depend on steel grade. Higher strength steels allow thinner sections, reducing crane deadweight and improving efficiency. Fatigue-prone areas may require reinforcement or use of higher toughness steel.

-

Hooks: The shape of the hook must accommodate stress distribution. Alloy steel forgings with rounded transitions reduce stress concentration, which prevents cracks. Material surface treatment, such as shot peening or induction hardening, can further enhance fatigue life.

5. Environmental and Operational Factors

Steel mills expose cranes to:

-

High Temperatures: Near furnaces, elevated temperatures can reduce steel strength. Material selection must account for high-temperature performance, such as using alloy steels with improved thermal stability.

-

Impact and Shock Loads: Handling steel slabs or ingots often involves sudden loading. Materials must combine high toughness with sufficient yield strength.

-

Corrosive Atmosphere: Moisture, scale, and chemicals can accelerate corrosion. While overhead cranes are usually indoors, protective coatings or weathering steel may be considered for extended life.

6. Quality Control and Testing

Proper material selection must be accompanied by rigorous quality control:

-

Mechanical Testing: Tensile, impact, and hardness testing confirm the material meets design specifications.

-

Non-Destructive Testing: Ultrasonic or radiographic inspection ensures the absence of internal defects, especially in hooks and welded girders.

-

Fatigue and Load Testing: Simulating operational conditions verifies the performance of materials under real-life stresses.

7. Conclusion

Selecting the right materials for 100-ton overhead crane girders and hooks in steel mills is a complex process that balances strength, toughness, fatigue resistance, and environmental adaptability. High-strength structural steels like Q345B, Q420B, and low-alloy steels such as 16Mn are widely used for girders, while forged alloy steels such as 40Cr, 42CrMo, and 35NiCrMo are common for hooks. Heat treatment, welding, and surface finishing further enhance material performance. Considering operational conditions, safety factors, and maintenance requirements ensures that cranes operate reliably, safely, and efficiently over their service life. By carefully selecting and testing materials, steel mills can minimize risks, maximize productivity, and protect both personnel and equipment from the hazards associated with lifting extremely heavy loads.