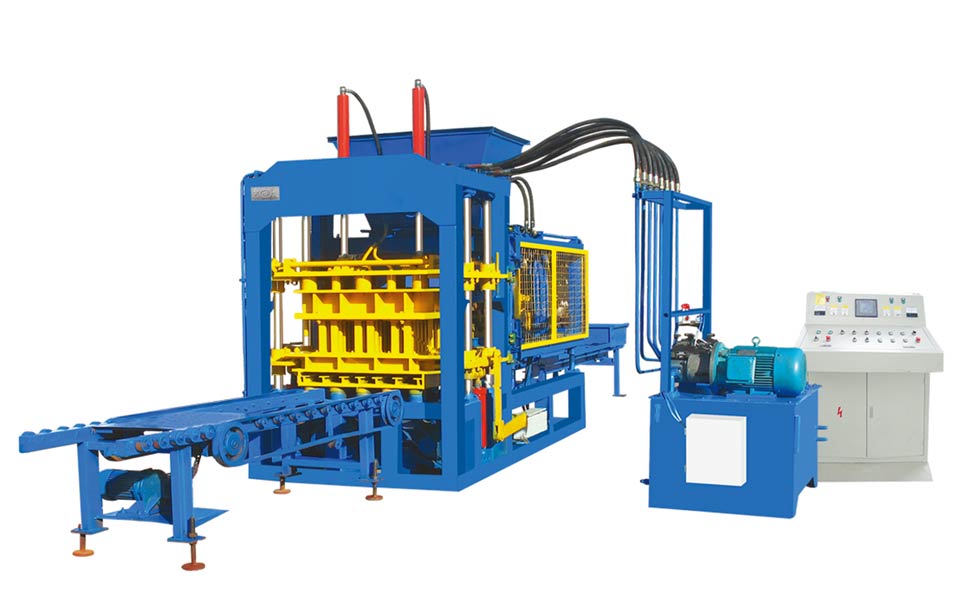

In this short post, we are going to discuss some of the features and benefits of fully automatic solid block making machines. There are lots of good reasons to invest in such a machine, especially if you all looking to scale-up your brick production business to fulfill larger orders in the coming years. So, without further ado, here are some of the core advantages of fully-automatic solid brick making machines:

• Efficiency

Fully automatic machines are engineered to run round-the-clock and are engineered to be energy efficient. The biggest machines can manufacture over 15,000 units per hour. The low running costs ensure that brick making businesses have healthy profit margins. While the high initial investment costs of fully automatic models can deter some buyers, the ROI rates are impressive and typically far exceed ROI rates of manual and semi-automatic block making machines.

• Automation

• Automation

A fully automatic solid block making machine really can automate an entire brick production line. The best models come with programmable centralized computer units that allow operators to adjust various parameters for the best end products. What’s more, top-rated machines don’t require much human oversight as they are equipped with sophisticated fault detection and automatic correction systems.

• Versatile

An automatic solid block making machine is a versatile, multi-functional piece of machinery. While it might have “solid block” in its name, by interchanging the molds and switching up the raw materials, it’s possible to manufacture a wide range of bricks with different properties. Examples include interlocking bricks, curbstone blocks, h-pavers, concrete hollow blocks, and much more.

• Eco Friendly

You can use a solid block making machine to convert industrial waste into various types of bricks. As a result, such machines can be categorized as eco friendly since they help to reduce the volume of construction waste sent to incinerators or landfill sites each year. Bricks manufactured from recycled waste are also much cheaper to make and thus offer businesses the opportunity to make larger profits. Furthermore, since modern block making machines are powered by electricity, they don’t emit any toxic air pollution during operation.

• High-Grade Solid Block Production

Since fully automatic block making machines are controlled by computers, there is no chance of human error during brick production. Consequently, provided the right raw materials are used and the human inputs into the control unit are correct, all blocks output will have a uniform shape, size, and density.

• Lower Manual Worker Costs

Due to the high degrees of automation of fully automatic brick making plants, brick production businesses stand to save a considerable amount on human labor costs. With such a plant, you can manufacture bricks 24 hours a day, 7 days a week.

Presented above are a few of the key features and advantages of a fully automatic block making machine. As you can see, investing in such a machine could bring many benefits to your business. That said, it’s important to ensure you only buy brick making machinery from reputable manufacturers. Look for vendors that have been in operation for a good span of time.